Technological Description. Features

"VAD"® Aquaculture Center : Aquaculture Farm, fish farm or land intensive aquaculture farm is defined as an industrial building designed

and developed with the sole purpose of fully executing the implantation and installation in its inside, of the Patented SRS® Production

System, technologically certifying the subsequent productivity and optimum exploitation of the aforementioned system.

Technological Characteristics

Sector : Aquaculture.

Sub-sector : Intensive production of fish in aquaculture farms or intensive land based high-tech fish farms.

SRS® Production System : Cultivation and fattening of fish, in shallow water streams in closed cycle, inside large vertically stacked rectangular trays, thus defining the SRS patented production system intensive, applicable to different aquaculture species, with total independence from their areas of origin.

Minimizing Soil : Reducing the soil need by 1000%, for the same production volume. The usual density of work for the rectangular tanks intensive system VAD, is 20 kg per m2., while the usual density of work of the aquaculture farms extensive is 350 gr. per m2.

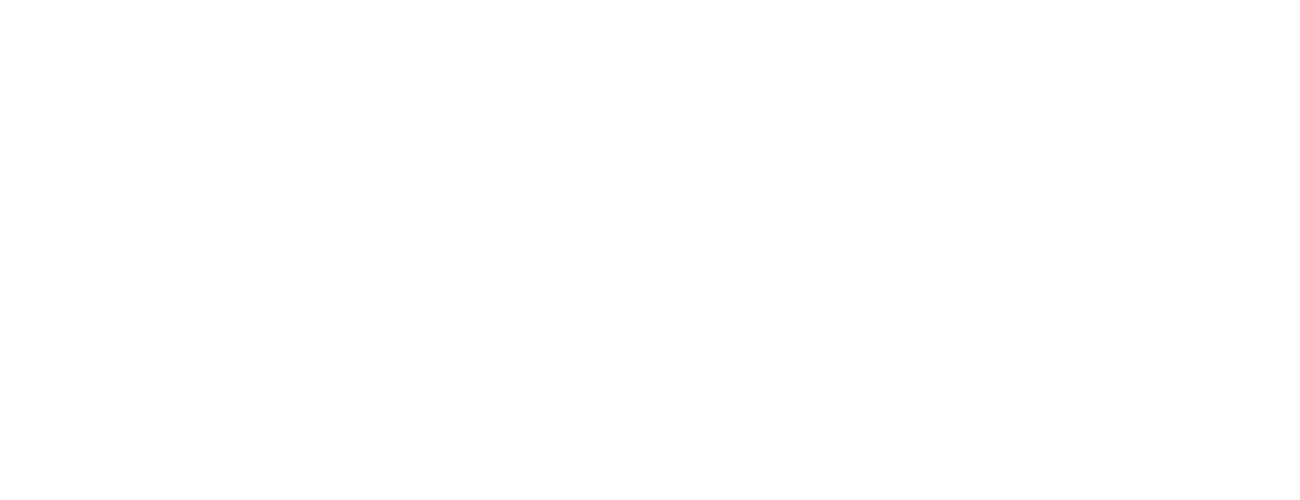

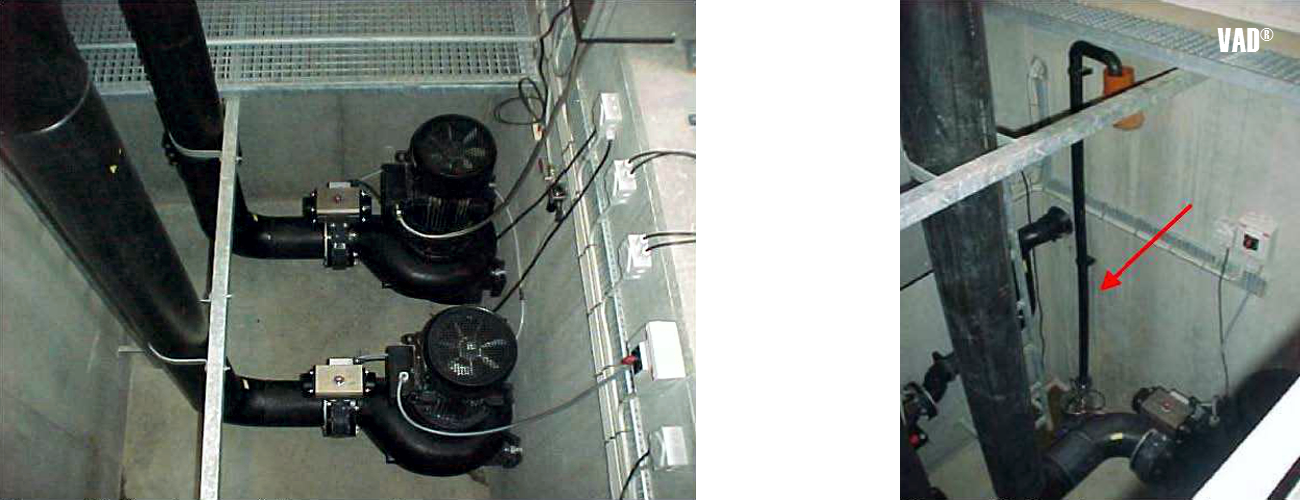

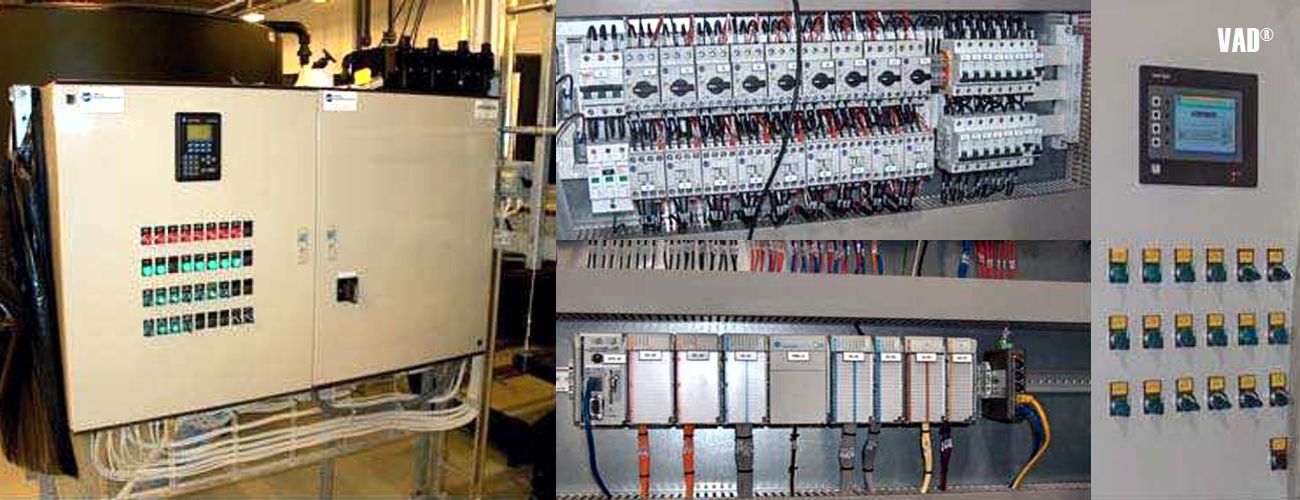

Minimizing Water. RAS (Recirculation Aquaculture System): Water requirement reduction up to 80%. The RAS system works in closed circuit with an estimated renovation of 5-10% per day.

Sub-sector : Intensive production of fish in aquaculture farms or intensive land based high-tech fish farms.

SRS® Production System : Cultivation and fattening of fish, in shallow water streams in closed cycle, inside large vertically stacked rectangular trays, thus defining the SRS patented production system intensive, applicable to different aquaculture species, with total independence from their areas of origin.

Minimizing Soil : Reducing the soil need by 1000%, for the same production volume. The usual density of work for the rectangular tanks intensive system VAD, is 20 kg per m2., while the usual density of work of the aquaculture farms extensive is 350 gr. per m2.

Minimizing Water. RAS (Recirculation Aquaculture System): Water requirement reduction up to 80%. The RAS system works in closed circuit with an estimated renovation of 5-10% per day.

WATER RECIRCULATION AQUACULTURE SYSTEM (RAS) – PURIFICATION PLANT

Temperature Control : The possibility of controlling the water temperature, maintaining the constant at 25 º, this means that the

fish are fattening all year round, thus reducing the growth period of fish from 16 months to 6 months. Under normal conditions in

the natural ponds of production, the aquaculture species when the water falls from 14 º C, enter in a period of hibernation, reducing

its metabolism, burying in the bottom and not feeding, therefore, without growing. This period lasts for six months (November-March)

per year, therefore, only is available six months of growth per year. With SRS® Production System, be maintained the constant temperature

at 25 ºC, the fattening and the growth be produced always independently of the production season.

Organic Aquaculture Production : Based on the breeding of fingerlings of aquatic species from ecological reproducers from ecological aquaculture farms, with compliance with the mandatory legal provisions of the Regulation (EC) on aquaculture ecological and the application of organic aquaculture production standards in relation to the origin of species, aquaculture practices, reproduction, food, sanitary and veterinary fields and cleaning and disinfecting protocols, that prevent waste of resources and environmental pollution.

Organic Aquaculture Food : According to Regulation (EC) Nº 889/2008 on organic feedingstuffs, diets are designed to prioritize the health of the species, the high nutritional composition for the different stages of its development guaranteeing a high quality of the final edible product and a low environmental impact. The organic feedingstuffs for carnivorous aquaculture species are obtained from organic raw materials of plant or animal origin, as fish meal, fish oil and ingredients derived from fish offal already captured for human consumption in fisheries certified as sustainable under a scheme recognised by the competent authority in line with the principles laid down in Regulation (EU) Nº 1380/2013 of the European Parliament and of the Council. In the larval rearing of organic juveniles or fingerlings, conventional phytoplankton and zooplankton may be used as feed.

Rationalize Food : Saving up to 20% more in food by automating its distribution, allowing an optimal utilization of the food resources, as well as the observation of better use of the same.

Health of the Species : It improves the visual control of the cultivated species due to the shallow water depth (5-20 cm), which allows to inspect them constantly to detect and prevent any possible anomaly.

Ecosystem : Reduction of the environmental impact by decreasing the precise terrain surface for the same amount of production, besides locating all the installations under the same volume or building, it limits and minimises the environmental impact .

Environmental Pollution : The suspended waste filtering system, together with the remaining residual water controls, ensure the lack of contaminants of all kinds. The fish farm is, at the same time, immune to the effects of external contamination caused by urban spills discharge, fertilisations of the annexed fields or other elements.

Biomass : Biomass production follows the productive patterns of the traditional system, as fish consume the same amount of food to fatten and grow, and consume the same oxygen in the development process. This system takes advantage many more the food supplied.

Organic Aquaculture Production : Based on the breeding of fingerlings of aquatic species from ecological reproducers from ecological aquaculture farms, with compliance with the mandatory legal provisions of the Regulation (EC) on aquaculture ecological and the application of organic aquaculture production standards in relation to the origin of species, aquaculture practices, reproduction, food, sanitary and veterinary fields and cleaning and disinfecting protocols, that prevent waste of resources and environmental pollution.

Organic Aquaculture Food : According to Regulation (EC) Nº 889/2008 on organic feedingstuffs, diets are designed to prioritize the health of the species, the high nutritional composition for the different stages of its development guaranteeing a high quality of the final edible product and a low environmental impact. The organic feedingstuffs for carnivorous aquaculture species are obtained from organic raw materials of plant or animal origin, as fish meal, fish oil and ingredients derived from fish offal already captured for human consumption in fisheries certified as sustainable under a scheme recognised by the competent authority in line with the principles laid down in Regulation (EU) Nº 1380/2013 of the European Parliament and of the Council. In the larval rearing of organic juveniles or fingerlings, conventional phytoplankton and zooplankton may be used as feed.

Rationalize Food : Saving up to 20% more in food by automating its distribution, allowing an optimal utilization of the food resources, as well as the observation of better use of the same.

Health of the Species : It improves the visual control of the cultivated species due to the shallow water depth (5-20 cm), which allows to inspect them constantly to detect and prevent any possible anomaly.

Ecosystem : Reduction of the environmental impact by decreasing the precise terrain surface for the same amount of production, besides locating all the installations under the same volume or building, it limits and minimises the environmental impact .

Environmental Pollution : The suspended waste filtering system, together with the remaining residual water controls, ensure the lack of contaminants of all kinds. The fish farm is, at the same time, immune to the effects of external contamination caused by urban spills discharge, fertilisations of the annexed fields or other elements.

Biomass : Biomass production follows the productive patterns of the traditional system, as fish consume the same amount of food to fatten and grow, and consume the same oxygen in the development process. This system takes advantage many more the food supplied.

VIKING AQUACULTURE DEVELOPMENT Ltd. Copyright © MADRID 2.018. All rights reserved.